Description

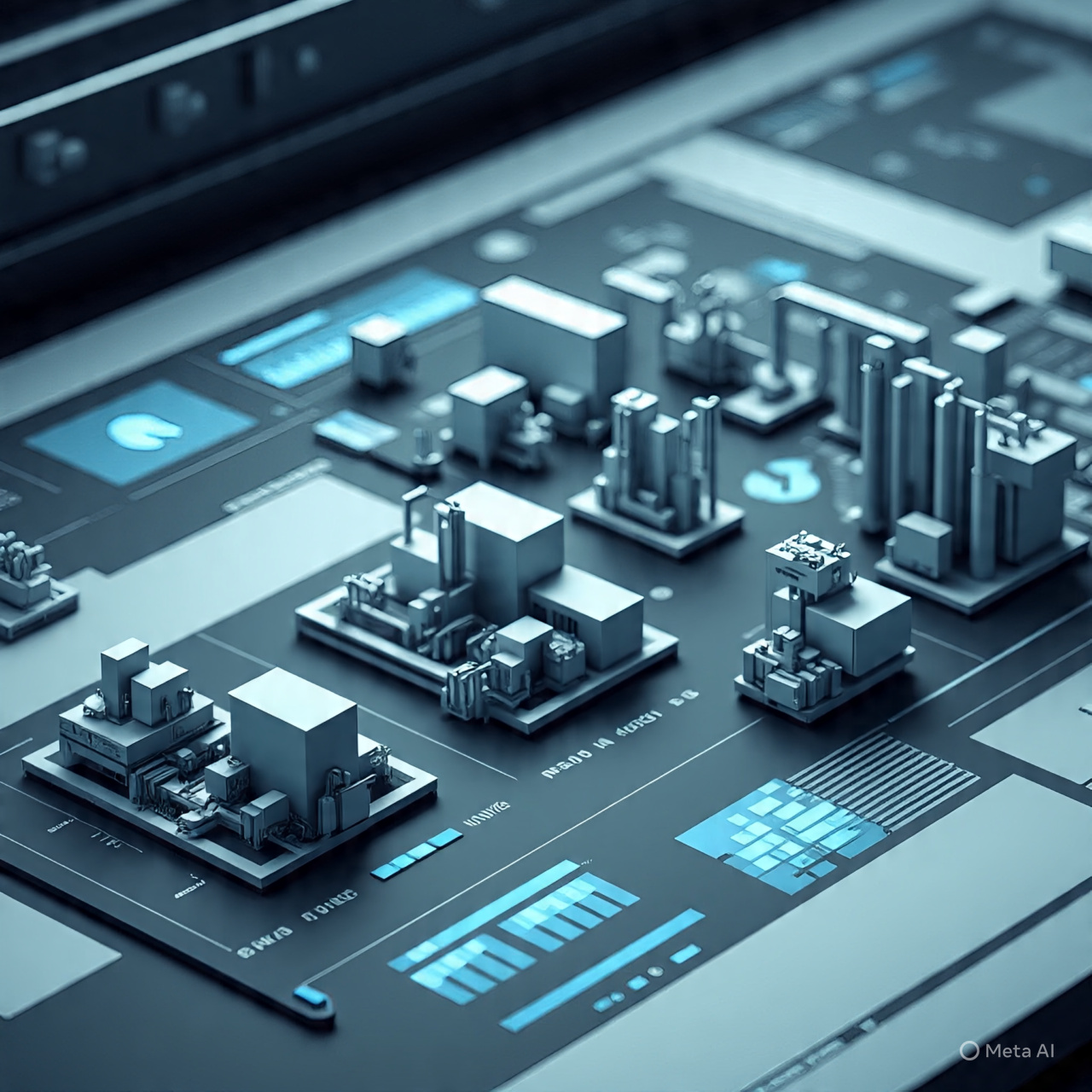

The Digital Twin Monitoring Service creates a dynamic, data-driven virtual model of factory environments, enabling operators to track machinery performance, detect anomalies, and simulate process improvements. By integrating IoT sensors, machine learning algorithms, and industrial control systems, it provides a comprehensive view of operational health. Manufacturers can test production changes virtually before implementation, identify efficiency bottlenecks, and predict maintenance needs, reducing downtime and boosting productivity.

Hellen –

Before, pinpointing bottlenecks in our stamping line was a weekly fire drill. ‘Digital Twin Monitoring Service for Factories’ provided immediate, granular visibility. Downtime dropped by 15% thanks to proactive alerts, and their knowledgeable support team swiftly addressed my initial integration questions. The intuitive interface sealed the deal.

Mulikat –

Digital Twin Monitoring Service for Factories” eliminated production blind spots overnight. Unexpected machine downtime plummeted; now we anticipate, not react. The intuitive interface made adoption seamless, and their support team expertly guided us through setup. We’ve seen a tangible 15% efficiency boost already.

Christian –

Downtime was a constant headache. Digital Twin Monitoring Service provided instant visibility into our bottleneck – the injection molding machine. Predictive alerts now let us address issues *before* they halt production. The intuitive interface and responsive support made adoption seamless. We’ve seen a measurable 15% jump in output.

Sadiya –

Digital Twin Monitoring Service” gave us immediate insights into bottlenecks on our assembly line we couldn’t see before. The intuitive interface made troubleshooting easy, and their proactive support team helped us configure alerts perfectly. Downtime decreased by 15% within the first month – a tangible ROI.